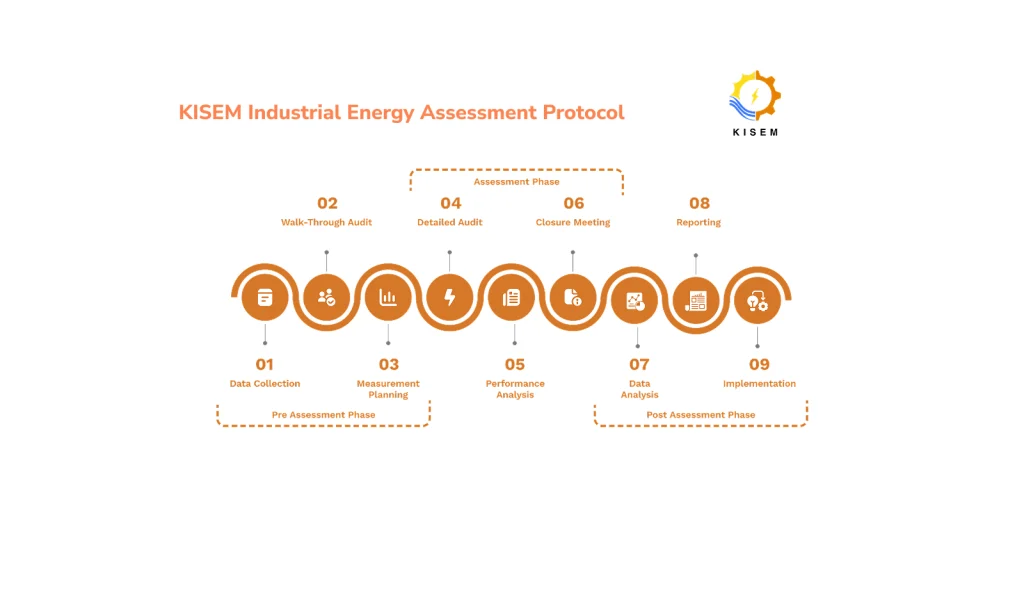

Pre Assessment

The pre-assessment form will be provided to the client. This form generally includes:

- Size of Plant and plant layout

- Industry type (NIC code) and process description

- Production levels, units, monetary values, operating hours

- A one-year history of utility bills

- List of major energy-consuming equipment

- Senior Executive in charge of the plant operation

- Plant manager

- Energy manager

- Environmental personnel

- Maintenance personnel

- Analyze the manufacturing process

- Chart and graph utility bills

- Analyze utility bills for trends and errors; establish the unit cost of energy

- Start Plant profile

- Identify key energy systems

- Review design and other technical documentation

- Identify possible energy saving potential recommendations using the KISEM database

- Develop Assessment Strategy

Assessment

- Introduction

- History of the KISEM program, the kick-off meeting

- Distribute case studies, tip sheets

- Description of the manufacturing process and operations

- Is this a typical day?

- Run through the process following the material flow

- Discussion of inventory levels

- Questions about defects, bottlenecks, and waste materials

- Present charts and tables of utility bills

- Plant Tour

- Conduct in the direction of the material flow

- Plant Manager to conduct a tour

- Only one person will ask questions

- Conceptual tour, no data taken

- Meeting room debriefing

- Discuss the process, ask questions

- Develop and plan for the afternoon

- Create specific tasks and divide them into teams

- Review notes and brainstorm

- Develop a list of potential energy-saving opportunities

- Ensure that everyone has clarity of process and potential recommendations

- Refine the List of opportunities to be investigated

- Decide what information needs to be gathered, measured, monitored

- Assign teams to specific tasks

- Make plans to meet at the assigned time and place

- Field Data Gathering (Only in Detailed) **

-Conduct Measurements, monitoring, and diagnostic testing- Motor systems

- Heat processes

- Cooling processes

- Water Use and pumps

- Ventilation

- Compressed Air

- Delivery and distribution systems

** In case of a walk-through Assessment for any of the key details identified, field data to be gathered.

- Closure Meeting

- Discuss findings with management

- The preliminary estimate of potential savings

- List out additional information required

- Prioritize recommendations of analysis

- Communicate on the list identified in the closure meeting

- Send out the mail if required in a specific format

- Follow up over calls and emails to collect maximum data

- Collate the details and classify them as required for the analysis

Post Assessment

- Conduct engineering and financial analysis

- Develop first-order estimates of implementation cost

- Deliver draft report to the client, upload data to KISEM database

- Contents of an KISEM Report

- Executive Summary including a summary of Recommendations

- Plant Description

- Process Description

- Resource Charts and Tables

- Major Energy Consuming Equipment

- Best Practices

- Description of Individual Energy-Saving Recommendations

- Follow-up and finalize Detailed Report

- Call the client within two weeks to get the feedback on the draft and discuss and mutually finalize Final Report

- Submit the Final Report to the client

- Update the data in the KISEM Database

- Follow-up Actions

- Call the client in two weeks to ensure delivery and answer any questions

- Follow up in 2-3 months for the implementation schedule of Recommendations

- Call the client in 6-9 months for implementation data

- Upload data to the KISEM database

- Inquire about the potential for a Case Study of the project(s)